Enhanced TDS

Identification & Functionality

- Chemical Family

- CASE Ingredients Functions

- Industrial Additives Functions

- Technologies

- Product Families

Features & Benefits

- CASE Ingredients Features

- Industrial Additives Features

- Product Highlights

- Stable viscosities and reduced set back properties

- Greater water retention

- Dried films that are clear and flexible

- Lower gelatinization temperatures

- Good compatibility and reactivity

Applications & Uses

- Markets

- Applications

- Applicable Processes

- Product Application

Clear Sizing Paper

Because of their excellent water holding and film forming properties, ETHYLEX starches are highly recommended for surface sizing papers. Availability in a wide viscosity range permits their usage at the size press or calender stack; ETHYLEX films give papers better surface strength and hold out properties than those provided by other starches commonly used. As a result, ETHYLEX starches are products of choice for surface sizing fine quality papers.

The properties of film clarity and continuity permit the use of ETHYLEX starches in transparentizing papers.

Size Press Paper Coating

EHTYLEX starches provide process advantages such as viscosity stability and improved runnability to metered size presses. These advantages are not seen in other starches. ETHYLEX starches are especially useful as co-binders in both clear and pigmented surface sizes in conjunction with synthetic resins, polyvinyl alcohol, latexes and other film formers. Hydroxyethylated starches are fully compatible with these materials, and act with them to contribute to the barrier properties that impede the migration of moisture, wax, lacquer and varnish.

Paper CoatingCertain grades of coated paper, such as label paper, require especially high print quality. ETHYLEX starches are used in these high-solids, pigment-binder systems because they possess unusually high adhesive strengths and provide good compatibility with latex. The ETHYLEX starches also contribute water holding ability, viscosity stability, and consistent rheological properties to coating mixtures. The trend to increased coating speeds necessitates the consistent, stable viscosities of ETHYLEX starches.Paperboard Sizing and Coating

ETHYLEX starches are important in the manufacture of a large variety of paperboard products, ETHYLEX® 2065 is used at the calender stack to control curl and to increase the hold out properties of the board for subsequent over coating.

Properties

- Color (Properties)

- Physical Form

- Appearance

- White to Off-White Powder

- Odor

- Starch

- Specifications

Value Units Test Method / Conditions Foreign Matter max.10 ppm TN32555, Visual Sludge (at 3%) max. 1.0 ml TN72528 Viscosity 600 - 1600 cps RVA DSB - TN90558 pH Value 6.0 - 8.0 - TN60550 Moisture 10.0 - 13.0 % TN46550 Color 6.0 - 9.0 - TN22570 Ash Content max. 1.00 % TN09560

Regulatory & Compliance

- Certifications & Compliance

Technical Details & Test Data

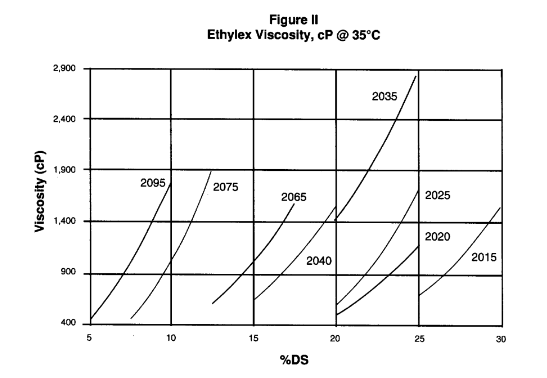

- Viscosity Graph

The typical viscosities shown in Figure II illustrate the broad range of viscosities covered by Primient’s ETHYLEX starch series. Differences in viscosity correlate largely to the degree of acid thinning and not to chemical substitution.

Packaging & Availability

Storage & Handling

- Shelf Life

- 730 days

- Storage Information

Store at ambient temperature and humidity.